VisionNav was founded in 2016 by a PhD team from the Chinese University of Hong Kong and the University of Tokyo. Visionnav is committed to applying artificial intelligence (AI), environmental perception, deep learning and servo control technologies to driverless industrial vehicles, and providing high-performance driverless industrial vehicles and unmanned logistics solutions.

Friday, July 24, 2020

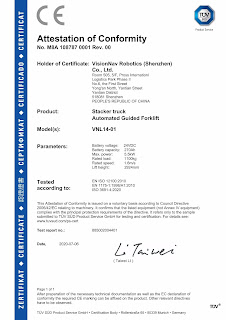

VisionNav Robotics received CE certificate under the latest standard ISO3691-4:2020 from TÜV SÜD.

NEWS FLASH | #VisionNavRobotics received #CEcertificate under the latest standard #ISO3691-4:2020 from TÜV SÜD.

ISO 3591-4:2020, continually evolving new technologies and industrial driverless trucks, raises higher level of #safetyrequirements to #AutomatedGuidedForklifts

Friday, June 19, 2020

VisionNav Robotics Announces 100 Million Yuan in Series B1 Investment

VisionNav Robotics, the leader of vision guided industrial vehicles

for material handling in China, announced that it has raised 100 million RMB in

Series B1 funding. The round was led by Lenovo Capital, with participation from

Flyfot Ventures and the existing investors Eastern Bell Capital.

The new capital will be used on R&D of visual control and

perception technology, accelerating new product introduction to on-demanding

industrial settings previously scheduled for 2021 and 2020, as well as support

the company’s business growth and market expansion.

Founded in 2016, VisionNav Robotics is one of the forefront

players in vision guided vehicles worldwide. VisionNav’s technology, which

combines visual controls, perceptions and 5G technology into their vehicles,

transforms standard industrial trucks into a new generation of automated facilities

in manufacturing, warehousing and logistics industries known as vision guided

vehicles (VGVs). They resemble standard forklift trucks but working completely

automatically because they come equipped with cameras, AI and sophisticated algorithms

to navigate in dynamic environments and transport goods to and from loading

docks, warehouses, production lines and other industrial settings.

“When considering warehousing automation, customers always seek

for quick deployment, high operation efficiency and short payback period,” said

Li Luyang, CEO and cofounder of VisionNav Robotics. Vision guided vehicle is a

versatile and cost-effective solution for different logistics nodes, such as

logistic parks, logistics warehouses, manufacturing warehouses, workshops,

factories, intralogistics within the airports and habors. “The same vehicle can

do many different jobs such as loading and unloading, picking and put-away, storage

and relocation, reducing initial investment and saving operating and

maintenance cost.”

VisionNav’s solution is not only about the vehicles, although

there are already 5 series of autonomous vehicles including pallet movers,

pallet stackers, reach trucks, towing trucks and combustion trucks. It also

includes robot control system for the integration with multiple-level system,

and goods position detection system for multi-object identification. The

solution helps customers from different industries to manage their process in

multiple dimensions. Many of VisionNav’s customers are from factory logistics

(automobile manufacturing, 3C, food and pharmaceutical, etc.) and warehousing

logistics (e-commerce, retail, 3PL, aviation, etc.), such as Amway, Walmart,

DHL, Cainiao, Gree, etc.

When it comes to company’s future growth, Li Luyang express

his ambition to play on the international stage. “We will take Southeast-Asia

as our first target market, then gradually expand our footprints to Europe and

America. It’s just a massive worldwide market with significant growth.”

http://en.visionnav.cn/show-32-152.html

Saturday, May 30, 2020

Review | DHL Supply Chain Team Visited VisionNav Robotics for further cooperation

DHL is one of

the best contract logistics suppliers in the world, who has always been a

strong supporter of innovation and change in logistics industry. On October 30,

DHL Supply Chain sent a team to visit VisionNav Robotics at the headquarters in

Shenzhen. During the visit, Dr. Fang Mu, the CTO of Visoinnav Robotics,

introduced their unmanned products and business mode to DHL team. Deepening

cooperation between two parties can be expected soon.

Figure:

DHL Supply Chain team visited VisionNav Robotics

"VisionNav Robotics

have profound technology research & development and long-term project

experience in the field of vision-guided unmanned forklift." Representative

from delegation team affirmed the professionalism of VisionNav Robotics visual

AI technology, and asked about efficiency and safety of unmanned forklift

technology when replacing labor. “It involves a large number of goods detection

and information reading processes. Although the efficiency of unmanned forklift

cannot reach the level of manual handling, by 24/7 longtime working with high

efficiency, it can meet the total needs of inbound and outbound in warehousing

companies" Dr. Fang Mu also introduced the unique safety protection module

in their forklifts, which can effectively avoid obstacles. Up to now, all launched

forklifts in operations are in good conditions and they can effectively adapt

to a variety of complex scenarios, providing a large number of data precipitation

and scenario reference for the diverse needs of subsequent users.

Figure:

Dr. Fang Mu, the Vice General Manager of VisionNav Robotics

Figure:

DHL Supply Chain Delegation Team

Later, the

delegation team visited the unmanned warehouse of VisionNav Robotics for the

handling demonstration. Dr Fang highlighted their vision navigation module, a

visual camera on top of the vehicle. Unmanned forklift perceives environment

through visual information. It saves various environmental information as

offline map, and compares the information between real-time image and offline

map during operation to locate and navigate. A seemingly simple unmanned

forklift in fact integrates the most cutting edge technologies including AI

vision, servo control and cloud storage, making it the most promising

industrial robot in the market.

Figure:

DHL Supply Chain Delegation Team at VisionNav Robotics Unmanned Warehouse

Video:

DHL Supply Chain Delegation Team Visited VisionNav Robotics

DHL has been a

long-term partner of VisionNav Robotics. In the previous cooperation, VisionNav

Robotics has provided intelligent warehousing proposal for DHL bonded

warehouse. It takes about 2 months to import the project. It can seamlessly integrate

to the existing WMS system and realize multi-machine collaborative unmanned

operation, avoiding the danger of high level shelf operation and improving the

warehousing efficiency by more than 20%. The visit of further enhanced mutual

trust between DHL and VisionNav Robotics, and increase the possibility of

international business cooperation.

Monday, May 11, 2020

Review | VisionNav Robotics First Show With Its New Technology in CeMAT 2019

2019 CeMAT Asia

attracted over 120,000 professional audiences and visitors from Germany, the

United States, Russia, the United Kingdoms, Italy, Japan, South Korea,

Malaysia, Israel and other countries and regions. Under the series theme of

“Smart Drive, Smart Logistics”, the show presented advanced innovation

technological achievements and solutions in domestic and international

logistics fields. As a pioneer domestic company in the field of vision

navigation industrial driverless vehicle, VisionNav Robotics unveiled its

unmanned solution to stack four layer cages, making the booth highly popular

and crowded.

Glimpse of New Trends in Smart Logistics

at CeMAT

With the rapid

development of economy and e-commerce, the word "Smart Logistics" has

frequently become the hot search in the major media in recent years. With the

explosion of orders, consumers require a higher level of logistics efficiency

and service quality. Thus warehouse logistics companies started to explore more

advanced and applicable devices and methods to increase logistics operation

efficiency and safety.

In CeMAT, major

brands have emerged. Both industrial robot giants and smart logistics new-comers

have launched their new products based on AI technology. From this exhibition,

we can see logistics industry empowered by AI technology has shown great

potential. Application of AI visual technology in information storage,

transportation and picking & sorting fields, which represents the future

development trend, is also becoming mature. There are huge breakthroughs and major

leaps in product maturity in particularly.

Figure: Automated stacking technology based on vision navigation

Unmanned Stacking Solution from

VisionNav Robotics Attracts Great Attentions

As early as

August 2019, the unmanned multi-layer cages stacking solution from VisionNav Robotics

has made its debut in the automotive manufacturing area. It has attracted plenty

attentions and favors of many intelligent manufacturing and storage companies.

The public appearance of this solution represents another breakthrough and

upgrade of VisionNav Robotics unmanned forklifts in precise stacking

application.

During the show,

VisionNav Robotics in particular presented the demonstration of cages picking

at random locations and stacking to high-level. Even customer move the position

and angle of the cage randomly, the unmanned forklift can still adjust itself

to pick and stack the cages accurately. “In the complex stacking scenarios, it

requires more flexibility when connecting automated equipment and manual

operations. For unmanned forklift, such flexibility is the self-adaption and

self-corrective ability to pallets and cages hat is randomly displaced by

human.” Officials from VisionNav Robotics introduced that the self-adaptive

cage stacking operation integrates spatial perception, pallet detection and

servo control techniques, which can help more intelligent manufacturing

companies, especially auto parts manufacturer a more safer, reliable and

cost-effective storage experience.

Video:

60 second review of VisionNav Robotics

Driven by Capital and Tech, Smart

Forklift Segmentation Develops Rapidly

From overall

industrial structure, when smart logistics continues to do well in 2019, some segments

have also entered a new ear, and industry segmentation has begun to take shape.

Compared to 2018, number of exhibitors who present unmanned forklifts in this

exhibition has accounted for half. As the most needed vehicles in the industry,

we can see forklifts still play a pivotal role in the logistics industry.

The emergence at

largely of unmanned forklifts this year is mainly motivated by both capital and

technology. With the breakthrough and application of vision technology,

unmanned forklift manufacturers with independent development capabilities are

increasingly favored by the capitals. During the exhibition, multiple

investment institutions visited VisionNav Robotics, consulted in detail about their

products and solutions, and gave favorable comments on the deployment of the

product and market at strategic levels get

The multi-layer cage

stacking solution showed in this exhibition is an active attempt for VisionNav

Robotics to enter unmanned forklift competition in high-end market. In the next

few years, VisionNav Robotics will launch more and more unmanned industrial

vehicles such as unmanned cranes, airport tractors, etc. In compliance with the

wish of "liberating global industrial vehicles", VisionNav Robotics will

continue to further explore. Future and

VisionNav Robotics can both be expected!

Wednesday, May 6, 2020

VisionNav Robotics, Leader of Vision Navigation Unmanned Industrial Vehicles

VisionNav

Robotics, Leader of Vision Navigation Unmanned Industrial Vehicles

Author: Huang

Manting from xzlrobot.com

Founded in 2016 by a team of professor and D.Eng. from the Chinese

university of Hong Kong, VisionNav Robotics becomes the dark horse in mobile

robot (AGV) industry in China With world-leading vision navigation technology

and strong explosiveness, it takes only 3 years to reach turnover of over 50

million RMB, which attracts tremendous attentions.

Focusing on vision navigation with

different technologies

Compared to other AGV navigation such as magnetic, QR code and

laser, there are three core advantages for vision navigation.

1)Strong Usability: Visual camera can obtain rich information such as color, texture,

etc. These can help mobile robots to achieve effective positioning, controlling

and perception in natural environment. It can greatly improve operation

efficiency, accuracy and stability, as well as reduce project installation

difficulties and shorten onsite installation time. Compared to other navigation

methods, vision navigation from VisionNav Robotics can adapt to complex

scenarios in the demand of customer’s regular use. For example, deformed racks or pallets after

long-time use, large proportion of oversize goods, unpredictable transportation

needs with periodical surge, vehicle dispatching and scheduling in narrow

space, etc.

2)Wide applicability: Adding modularized vision navigation

technology to industrial vehicles can easily realize unmanned transformation

and upgrade. At present, VisionNav Robotics can work with over 180 industrial

vehicles from 6 brands.

3)Cost-effective:

Cost

advantage of vision sensors has significantly

reduced the price of the product.

The price of industrial camera from world’s top-level supplier is around 3000

RMB, which is 10%-20% of the price of same level laser sensors. Therefore, in terms of ROI or

payback period for end customer, there is an obvious advantage for vision

navigation unmanned industrial vehicles.

It takes 9 year

(6 years before company establishment and 3 years after) for VisionNav Robotics

team to make “unmanned industrial vehicles driven by vision navigation

technology” in the worldwide. The vision navigation unmanned industrial vehicle

modules and vehicle scheduling system self-developed by the team lead the standards

of underlying positioning, perception and control logic in international robotics

technologies. There is extremely strong product competitiveness in both

domestic and global market.

Dr. Li Luyang, co-founder of VisionNav Robotic told reporter from

xzlrobot.com in an interview earlier, that “VisionNav

Robotics is still working on vision navigation technology at the current stage.

By improving the information acquisition ability and information transmission

speed, vision and motion of industrial vehicles can be combined in a more

perfect way, which can further improve the easy-to-use, applicability and

cost-effectiveness, and promote the inflection point of industry.

Video: Mr. Li Luyang from VisionNav Robotics interviewed by

reporter from

xzlrobot.com

Lead globally in vision unmanned

industrial vehicles area with large amount of applications in head customers

VisionNav Robotics is a company providing a platform to do

unmanned transform and upgrade to industrial vehicles. Their business includes

unmanned industrial vehicles development and transformation in production

lines, warehouses, logistics parks, airports and other semi-structured

scenarios. It is reported that vision navigation unmanned industrial vehicles

from VisionNav Robotics have been applied successfully in over 30 sites from

industrial head customers.

There are 2 advantages of VisionNav Robotics, which will keep the

leading in vision navigation unmanned industrial vehicle area.

(1)

Technical

accumulation. For 9 years VisionNav Robotics has been working on vision

navigation field in depth. With the

help of their world-class team they will continue to increase spending

in vision navigation R&D in the next 3 years to build higher technical barrier. “The responsibility of leading

enterprises in the industry is to promote the appearance of industry explosion

breaking point. VisionNav Robotics is make its own efforts. Whether there is explosion

breaking point for vision navigation in the fields of unmanned industrial

vehicle, the decisive factor is not market demands, but technology and product. It is fair enough to say that there are no any unmanned industrial

vehicles of any companies worldwide can fully meet the customer's requirement

on efficiency, function, cost, and vehicle reformation.Therefore we will not

feel any comfort for the current situation, instead we should increase the

investment on R&D, strive forward with our whole heart and mind and never

stop working deeply on vision navigation and products until our technology and

project can fully meet customer’s requirement.” Dr. Li Luyang emphasized in the

interview.

(2)

The landing of mature business mode helps to

accumulate rich project experience. Vision navigation unmanned industrial vehicles and systems from

VisionNav Robotics is known to apply successfully in many fields including

ecommerce logistics, retail logistics, bonded logistics, FMCG, automotive

manufacturing, new energy, and so on. More than 60% of their customers are the

world’s top 500 companies. VisionNav Robotics can provide solutions for complex

scenarios, many of them are industry first and advanced, such as 9.4m high

level unmanned loading on racks, self-adaption picking and placing goods

technology, real-time positioning with correction technology. These can

creatively solve the difficulties to automatically transport irregular parts. During

2019 CeMat Asia, VisionNav Robotics exhibited their vision navigation control

module, and the world’s first highly precise stacking solution of multiple

cages. “In our industry, all valuable technologies and products need to be

precipitated and excavated by a large amount of customer requirements and

application scenarios, then force engineers to verify their R&D result in

customer actual requirement and applications, then again force back the

engineer for continuous iteration. If you only make a laboratory prototype or

only deploy at 1-2 customer sites, there is still a long distance for volume

production, because you may even understand the actual requirement of your

customer. The advantage of VisionNav Robotics lies in technology and product continuous

iteration via large numbers of customer sites and applications. Their R&D

team nevel alienate themselves from their customer to optimize products at the

gradient directions, so that they can do at fastest speed of growth with

highest efficiency.” Explained by Dr. Li Luyang about his thought of the

relationship between customer needs and R&D.

As for the development in the future, Dr. Li Luyang said “the

easiness, adaptability and cost-effectiveness of vision navigation technology

needs continuous optimization. We will always adhere to it. Base on this, we’ve

developed big outdoor scenarios using unmanned tractors in the airport. It will

gradually extend to other important application scenarios such as wharfs. The

goal of VisionNav Robotics is to become world leading company providing

universal platform of precise driverless technology.”

Sunday, April 26, 2020

With vision technology, VisionNav Robotics is solving something in real demands with its forklift AGVs

In the new era of unmanned logistics, warehousing becomes initial

strategic point

Unmanned technology has become a heated topic in logistics industry since

the beginning of the year 2020. The epidemic

outbreak hits existing industries real hard, but also brings some opportunities

–the restarting driverless vehicles are setting off another wave of robots

replacing human. With expedited release of market demands and the support of

technology and capital, unmanned logistics will enter a new era.

Looking from its overall structure, a logistics system can be viewed

as a crisscrossed network, the connected nodes are logistics centers,

enterprise warehouses and regional distribution points, and the interlaced

lines are transportation services such as trunk transportation, branch transportation,

and last-mile delivery. While road transportation using self-driving cars is

still in the attempt, the technology of automatic warehousing seems to be more

mature and is gradually becoming a strategic move in unmanned logistics.

|

| Unmanned Logistics Full View |

Forklift AGV has great potential with increasing needs of unmanned

transportation inside the warehouse

Driven by market demands, technology development and other multiple

factors, the unmanned process to replace traditional warehouse system has been accelerated.

Automatic equipment inside a warehouse mainly include automatic sorting robots,

wearable devices, cargo identification devices and forklift AGVs. While automatic

sorting technology is still developing, cargo identification techniques are

work-in-process, the most mature forklift AGVs with high cost-effective are much

more popular.

According to the data released by CITA, the total sales volume of

industrial vehicles in China are more than 600,000 units in 2019, indicating 2%

increase compared to the previous year. Thereinto, about 298,600 units are

forklifts in indoor warehouses, which makes up 43% of the total number. In

addition, there is a growing trend for forklift in recent years. With the

gradual deepening of “robots replacing human”, demands for forklift AGVs will

be more and more obvious indicating a huge market potential.

|

| 2019 Industrial Vehicles Total Sales Volume in China |

Complicated Intensive Storage Scenarios Are What Forklift AGVs

Needs to Overcome

When it comes to operations inside the warehouse, there are mainly 2

scenarios for forklift AGVs to replace manual forklifts: 1. truck loading, different

trucks such as cube, wing opening, flatbed, etc., in the environment of loading

platform, factory/ in-house or container yard; 2. Intensive storage scenarios,

including drive-in racks, beam type racks, narrow aisle racks, double deep

racks, shuttle racks, stack racks and other pallet racking. With the deepening

of automation integration and unmanned conditions getting mature, indoor

intensive storage become the main scenarios to use Forklift AGVs.

|

| 6 Types of Racking in Intensive Storage |

“Space utilization of intensive storage for middle or high level racking is relatively high, making it one of the major storage types at present. Besides, complicated working condition of intensive storage scenarios raises higher requirement for forklift AGV at the same time.” said Dr. Li Luyang, CEO of VisionNav Robotics, one of the representative enterprises for visual driverless industrial vehicles in China. These requirements mainly are:

1) Higher accuracy: considering

task completion and safety in the warehouse operations, there are higher

requirements for forklift AGV in terms of positioning accuracy and operation

accuracy.

2) High flexibility: forklift

AGVs need to improve the flexibility and self-adaptability in order to cope

with non-standardized manual operations, changes of different carriers, changes

of operating space, etc.

3) High efficiency: as the

entire logistics industry is speeding up, the advantage of forklift AGVs

replacing manual forklifts is mainly lies in its efficiency.

4) Safety protection: the

overall protection is not only to identify and avoid obstacles during the

driving, but also to consider risks in high position and high-level racks

operations, for example for safer technology is required for drive-in racks,

narrow aisle racks, moveable stack racks, etc., to protect human, vehicles and goods.

With vision techniques, forklift AGVs can be widely applied in

intensive storage scenarios

To solve

current problems faced by forklift AGVs in the intensive storage scenarios, we

must highly rely on in-depth researches and innovations. When talking about industry development, Mr. Chen Baoqiang, deputy

director of the National Engineering Quality Supervision and Inspection Center,

emphasized the importance of in-depth technology innovations. “Lack of

innovation means lack of driving force for industry progress. There will be no

innovation without in-depth research.”

Dr. Li Luyang also said during an

interview with the reporter from XZL Robot Full-media, that the urgent tasks

for forklift AGVs is to improve their level of intelligence. “You can simply

view it as the robot ability to deal with non-standardized situations onsite,

which is definitely based on the understanding and learning of the environment.

Therefore vision technology is now the only way to improve forklift AGV

intelligence, which is also what VisionNav Robotics has been working on for the

past 3 years since the establishment.”

|

| Vision Navigation Forklift AGVs for High Position from VisionNav Robotics |

Visual sensors is also one

of the heated topics in the fields of unmanned forklift researches. Compared to

traditional laser sensors, visual sensors have stronger abilities of

information acquisition, and better systematic expandability: (1) there are 5 million points of information in a 5-megapixel

photo, and if 10 photos are acquired and processed in a second, it is equivalent

to acquiring 50 million points of information; (2) the points in the photo contain

more information than laser such as colors and patterns, providing a large

amount of valuable information for positioning, control and environmental

perception; (3) the perfect combination of vision and 5G in the future enable

us to transmit image information to the cloud through high speed network for

edge computing, or transmit to the serve for parallel computing, further

improving the performance of vision navigation by a large margin.”

It is learned that VisionNav Robotics has been working deeply in the

fields of vision navigation technology. With its unique techniques, rapid

growth and strong explosive ability, VisionNav Robotics is the first company to

complete reach truck unmanned modification and application for high level

operation. They also overcome the challenges of stacking racks up to 4 levels

precisely, which is one of the most difficult operations in the fields. Such stacking

techniques have already been practically applied in an automatic warehouse of an

auto parts manufacturer giant in South China. For the past 3 years, vision navigation forklift AGVs developed by

VisionNav Robotics have been accumulated applied in over 150 complicated

scenarios, including automatically picking and placing cargos from/to middle

and high levels in domestic intensive warehouses of many leading enterprises in

logistics, bonded, FMCG and other industries.

Application

1: Vision Navigation Forklift AGVs from VisionNav Robotics and its Application

of Stacking Racks

Difficulties: stacking 30 different types of stack

racks with wheels in random positions is a great challenge for forklift AGVs in

terms of intelligence level and operational accuracy.

Application

2: Vision Navigation Forklift AGVs from VisionNav Robotics and its Application

in High Level Beam Type Racks

Difficulties: compared to horizontal transportation, picking

and placing cargo from/to high positions requires further detection of the

storage locations, and such detection takes more time, therefore forklift AGVs

should make a perfect balance among efficiency, accuracy, intelligence level

and safety.

Application

3: Vision Navigation Forklift AGVs from VisionNav Robotics and its Application

in Drive-in Racks

Difficulties: there is limited space in the drive-in

racks, therefore the positioning accuracy and operational accuracy requirement

for forklift AGVs is the highest among all types of racks; in addition, moving

pallets like playing Klotski while keeping up with transportation tempo at the

same time is also a big challenge for forklift AGV operation efficiency.

It is reported that VisionNav Robotics will further focus on the

common requirements and pain points of forklift AGVs, developing applications

for outdoor truck loading, improving application range and depth of driverless

industrial vehicles, and providing highly effective solutions to more and more enterprises.

Monday, April 20, 2020

Product Testing of forklift AGV VNMR15

Sharing our latest video of our latest forklift AGV VNMR15 with:

1) Vision navigation

2) Cargo identification

3) 3m lifting height

4) ultra+ laser scanner

5) automatic label scanning

6) automatic charging

Your best choice for low-level rack shelves in the warehouse!

|

| ForkliftAGV |

|

| ForkliftAGV |

|

| ForkliftAGV |

Monday, April 13, 2020

High-Flex Automated Warehouse Solution Applied in Auto Parts Industry

Abstract: Affected by the change of international automotive

consumption structure, OBM dynamically adjust their capital investment in

R&D, manufacturing, management and many other aspects. Flexibly automatic

warehousing solution has become the first choice of many B-end customers

because it can increase storage capacity and reduce unit storage cost.

|

| Warehouse of Auto Parts |

Rigid

Transportation Demand for Auto Parts Manufacturer

A few days ago, VisionNav Robotics completed the implementation of

an unmanned warehousing solution for a auto parts manufacturer giant in South

China. The company is a Sino-Japanese joint venture with an area of nearly

130,000 square meters. There are more than 1,500 employees and the total number

of storage locations per floor is more than 5,000. Its main business includes manufacturing

of stamping and welding parts for car body, the design and manufacture of

stamping die for the covers of car body, tire of the car, car fixtures, design

and manufacturing of inspection device, etc., which indicates huge demands of

material handling.

|

| Automotive Auto Part Production Line |

Unmanned Stacking Solution for Stamping Die for the Covers of

Car Body

There are multifarious types of auto parts in the factory. Welding

workshop of car body covers and finished goods stockpiling area are located in

a square area on the first floor. After finishing stamping, welding, quality

inspection and other production processes in the central area, each 10-12 parts

will be put into the same frame and manually transported to the nearby

temporary stockpiling area. All the trucks are waiting at corresponding

platform for loading and then send to downstream final-assembly workshop for

car assembly process. Because the size of auto parts are so different, there

are 50 different types of material frame in use for storage in the factory.

|

| Irregular Auto Parts |

|

Auto Parts Stockpiling Area

|

Business

Pain Point

From the lean production prospect, there are significant wastes

during the production activities, which can be summarized as below:

- Redundant transportation —— unnecessary goods movements;

- Waiting

—— it’s easy to have “traffic jam” during the peak of

delivery bringing waiting; Late delivery or service in upstream production

activities causes work delay in downstream final assembly workshop, which

thereby will have impact material deployment plan for the next cycle.

- Excess

operation —— unnecessary operation during the work; Operators

need to confirm twice before loading to the truck, such extra process reduces

working efficiency.

- Manual forklift varies in operation efficiency, it takes less than 2 minutes to stack the first 2-3 level of the cages, but working efficiency drops at a rate of 50% for 4-6 level due to the changes of the height and angle.

|

| Workers Manually Transport the Goods |

Unmanned

Warehouse Solution

We provide solutions considering four aspects, which is functional

positioning, process optimization, personnel streamlining and equipment

upgrading:

All stockpiling areas will be divided into function units

of 100 square meters. 7 units which are closer to the outbound platform is used

for quick deliver and only keeping ready-to-go cages for the day. Other

finished goods will be stored uniformly into the stockpiling units that away

from the platform.

Set up fixed route for material transfer from production

line to stockpiling area, and use 8 pallet forklift AGV to complete the

transportation, not including truck loading. Travel distance for each vehicle

is no more than 100 meters.

- Use 1 VisionNav Robotics counterbalanced forklift AGV to stack cages automatically in each stockpiling unit. Not using manual forklift anymore, and it will only takes 1 operator to work 3 shifts in each stockpiling unit.

- For the problem of different cage specification, adding self-adaptive fork arm function in the automated forklift enable to accurately fork and pile cages according to different distance and height in three dimensions.

|

| Operation of the Unmanned Forklift |

Overall

Benefits

- Carrier: the number of manual forklift and forklift driver reduce by N-1 when using unmanned forklift;

- Flow Direction: clearer flow direction from production line to stockpiling units has been specified to reduce waiting time and traffic jam of the forklifts

- Capacity: unmanned forklift works continuously and completes stacking of 600-700 material cages stably every day;

- Flow Travel: save 1km driving mileage for each forklift

- Flow Efficiency: stabilize the supply to downstream components, reduce the fluctuation range of the production and distribution plan, and improve overall production efficiency by 70%

|

| Automated Stacking Operation Area |

Automated Stacking Solution for Car Tyres

Considering the great benefit of cage stacking in the first phase,

currently customer plans to launch the second phase project, car tyres unmanned

transportation. The transportation process for the tyres is relatively simple.

The warehouse is mainly for storage; and all the tires are packed into material

cages of same size and specification. There are 10 tyres in each cage and the

height of a cage is about 1.5m. The idea is to have 6 cages stacking on top of

each other in each location to maximum the utilization of storage space.

The biggest problem is when stacking to 4-6 layers, the operation

efficiency of manual forklift drops dramatically, while coefficient of unsafety

increases. The solution from VisionNav Robotics is to use their reach forklift

AGV, which is capable for 9m stacking. It takes on average 15 minutes for each

process, and such stability becomes the biggest advantage when no rush delivery

is required.

|

| A Demonstration of Stacking 3 Layer Cages for Car Tyre |

Technology of Irregular Part Unmanned Transportation Scenario

Is Mature Now

For manufacturing industry, stacking material cages / frames is

rigid demand. Compared to the racks, cages can make better use of the space in

a warehouse. For low level stacking (2-3 layers), manual forklift have more

advantage than unmanned forklift; for high level stacking (4-6 layers),

however, unmanned forklift have more advantage in turn. The advantage of VisionNav

Robotics unmanned forklift lies in its fork arm self-adaptive adjustment, and

real time positioning deviation correction, which can bring stable efficiency

to load and unload goods every time, and lower operational danger. It’s a great

benefit for plants and warehouses with large areas and large scale of massive

production.

VisionNav Robotics have rich experience on handling complicated

scenarios, we’ve identified and stack cages and frames with over 150

specifications accurately and automatically so far. Recently, VisionNav

Robotics is preparing a new test for irregular part unmanned transportation

project. Apart from the iteration of fork arm self-adaptive function 2.0

version, the algorithm about robot control and perception level has also been optimize

and upgraded. And for further information, please stay tune and find more details

in the upcoming application updates.

Subscribe to:

Comments (Atom)